Nordost is a technology-based company. Over the nearly 30 years in which we have been contributing our world-renowned audio cables, power products, and audio enhancers to the hifi industry, we have differentiated ourselves from the noise through our technology. We are confident that our groundbreaking proprietary technology and unique and precise manufacturing practices are directly responsible for the success of our products. To understand Nordost, and to understand Nordost’s products, you first have to have a clear understanding of the technology that we have developed over the years and use as the defining features of our cable ranges. To clarify those technological capstones, we have put together a brief explanation of some of Nordost’s technologies to help you better navigate our product offerings.

MICRO/DUAL MONO-FILAMENT WRAP

Mono-Filament technology refers to Nordost’s patented process of separating the conductor from its FEP insulation. During production, each conductor is intricately and uniformly wrapped in either a single strand (Micro), or a twisted pair (Dual) of FEP Mono-Filament, before being encased in an extruded layer of high quality FEP. This highly precise process allows every conductor to be surrounded by its own air dielectric. This revolutionary insulation process is directly responsible for the dramatic increase of signal speeds and excellent mechanical damping found in Nordost cables.

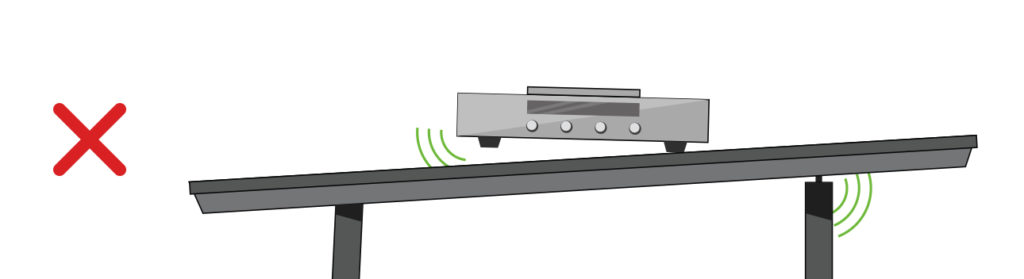

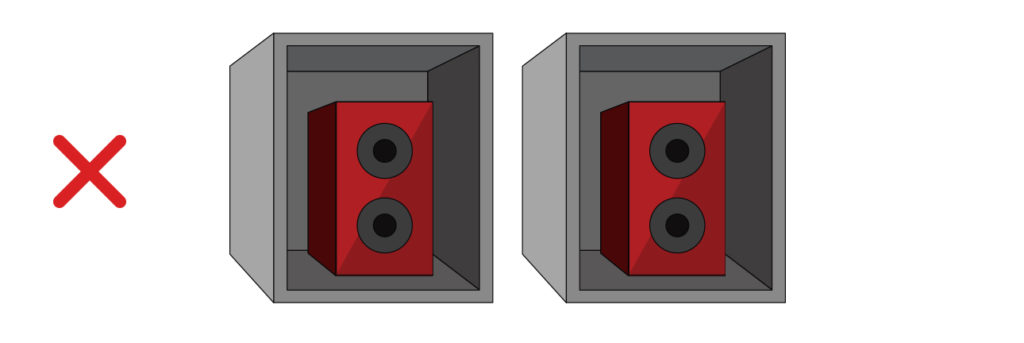

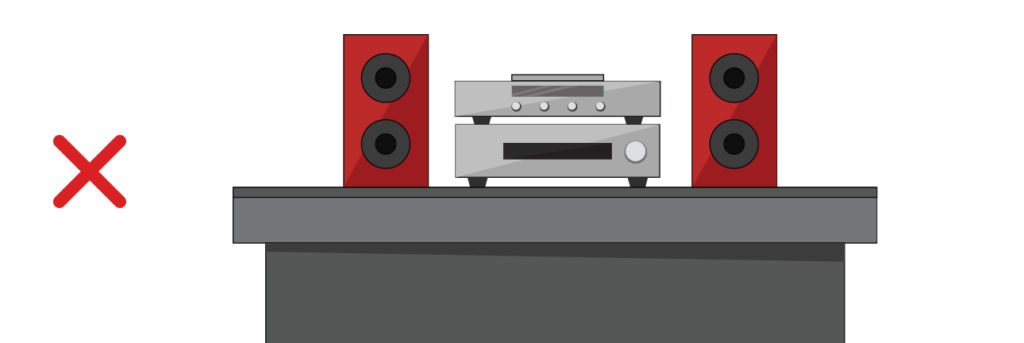

FLAT SPEAKER CABLE DESIGN

Due to the intricate extrusion process that Nordost employs, we are the only audio cable manufacturer able to achieve a flat cable geometry in our speaker cables. The flat nature of Nordost’s cables enables the following benefits: an increase in signal transfer speeds, the elimination of strand interaction, the optimization of the mechanical spacing and layout of conductors, a decrease in skin effect, and a reduction of physical surface contact.

MECHANICALLY TUNED LENGTHS

By analyzing the natural resonances of conductors, we have derived a proprietary formula to determine the optimal length of each cable, according to their unique geometry. By ensuring that the conductors are cut to these specific lengths, we maximize the sonic performance of our cables, eliminating timing errors.

HOLO:PLUG® CONNECTORS

These low mass, high end, connectors are designed to seamlessly fit the internal geometry of each individual cable that they house. HOLO:PLUG® connectors are the perfect marriage of electrical and mechanical tuning, allowing Nordost to have complete control of our highest quality interfaces—not only of the cable itself, but from end to end.

TOTAL SIGNAL CONTROL

In utilizing TSC shielding on our Supreme Reference cables, we are able to maintain the integrity of signal transfer while protecting our cables from the electrical pollution produced by RFI and EMI. When paired with our patented HOLO:PLUG® connectors, TSC provides 100% total shield coverage without the rigidity that is associated with other shielded cables.