Along with poor grounding, unwanted vibration may be one of the most ubiquitous problems in hifi. Damaging vibrations, no matter the source, have the ability to alter sound causing distortion, disrupted imagery, and even timing issues to the music you’re trying to enjoy. Not only is vibration a ubiquitous problem in hifi, but it’s pervasive throughout the system– affecting your components, loudspeakers, audio racks, and even cables. Luckily, ridding your system of unwanted vibration can be easy.

Nordost has not only introduced one anti-vibration product, but an entire Sort System made up of three products that are uniquely specialized to combat vibration, depending on the element of the system they are addressing. Unlike other anti-vibration products on the market, which define themselves as either isolation/de-coupling or coupling devices, Nordost’s Sort System takes a different, more comprehensive approach: resonance control. (For a deeper look at the difference between isolation, coupling, and resonance control, check out our blog: Three Ways to Address Vibration Control). The following will help you better understand each of Nordost’s Sort devices and show you how they fit into your system to help you rid unwanted vibration.

The Sort Kone is designed to address vibration occurring within components. It is built using a unique three-part construction, which creates a mechanical diode. When pressure is applied to the Kone, a one-way path is established through which the internal vibration produced by moving parts in the chassis of electronics can escape. When you place Sort Kones under audio components (a minimum of three Sort Kones per unit is required) music becomes more focused, there is an increase in depth and transparency in system performance, and the dynamic range is broadened. Nordost Sort Kones are available in three levels of performance (aluminium, bronze, and titanium) to fit a wide range of system and budgetary needs.

The Sort Füt is a mechanically tuned resonance control device designed to address the vibration generated both within loudspeakers and through audio racks. It is purpose-built to enhance the performance of your hi-fi system and improve upon standard spikes and stabilizers. The Sort Füt’s proprietary four-part construction eliminates unwanted vibrations by providing a direct ground path out, allowing extraneous energy to escape either the loudspeaker or audio rack it is attached to, while simultaneously preventing external vibrations from traveling back through the device. The result: a reduction of intermodulation distortion, a proliferation of musical information, and an increase of tonal and textural details that will allow your system to achieve the dynamic range it is capable of.

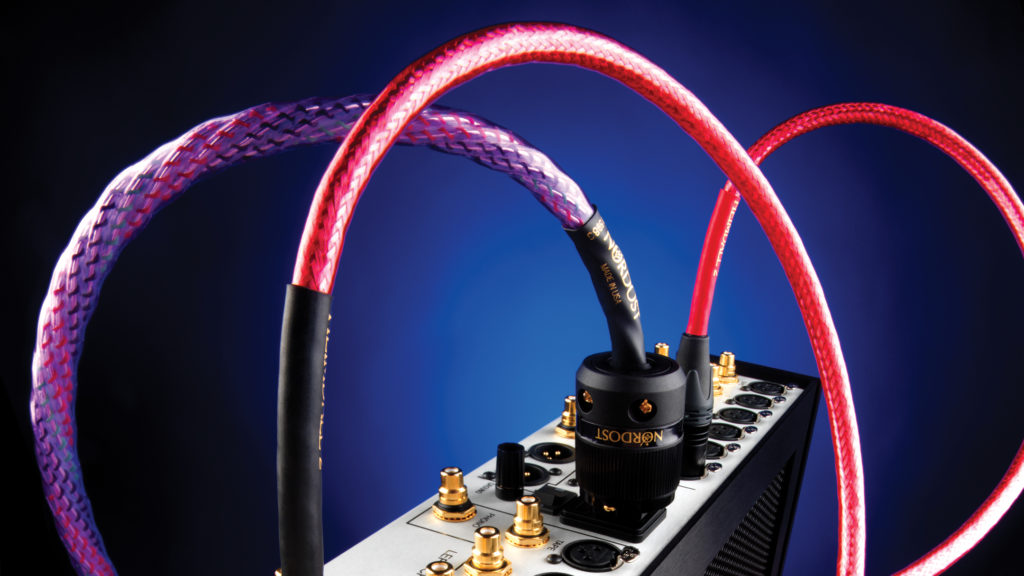

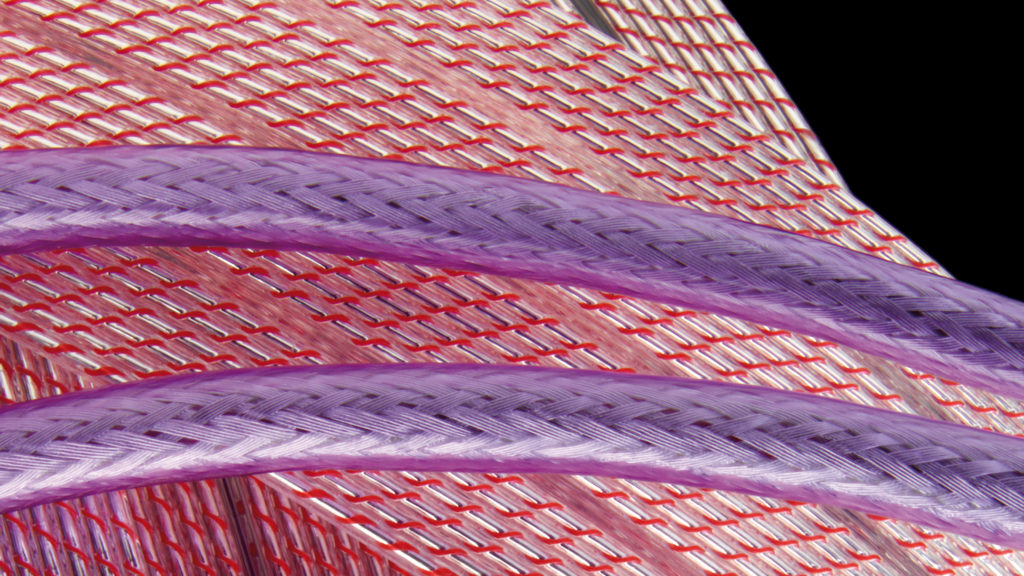

The Sort Lift is designed to minimize the points of contact that cables make with the ground and reduce boundary effects, without negatively affecting the resonant properties of the cables themselves. Each Lift is composed of two integral components: the base and the springs. The base inhibits any transference of electrical charge from the floor to the cable and eliminates static build-up on the dielectric itself. The springs use flexible, titanium alloy spring-wire, which makes up both the support wings and tension wire supports. Both elements of this floating spring system are coated in FEP, mirroring the design of Nordost cables and making the supports an extension of the cable jacket, eliminating any electrical interference, while allowing the cables to maintain their natural resonance properties.

To learn more about our Sort System or to arrange a demonstration, contact your local Nordost retailer.

For more information about vibration control, including how to identify different types of resonances, their sources, and how to manage those harmful vibrations, so that you can enjoy your sound system to its full potential, download our guide, The Importance of Vibration Control, today.